Metrology Laboratory | Calibration certificates

Calibration Certificates issued by Gesa Termómetros, S.L.

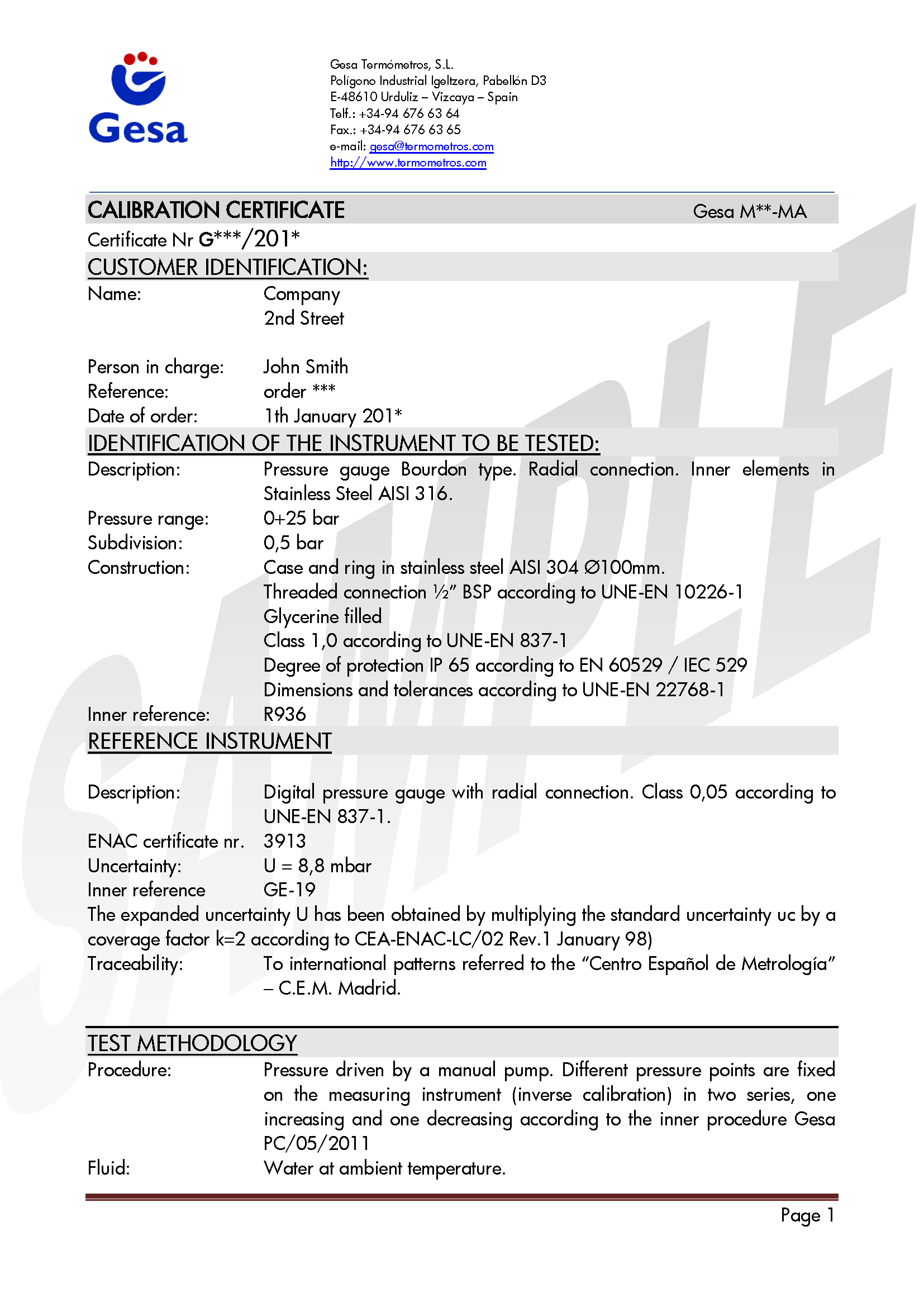

A calibration certificate is a document which shows the measurement differences between the instrument under test (measurand) and the standard values. The document must include the uncertainties of the measurand obtained in each calibrated point.

In the Gesa Termómetros S.L. Calibration Laboratory, we can calibrate instruments made in Gesa or in any other company.

Our certificates contain the next information:

- Points to calibrate (usually chosen by the client).

- Measurement differences between the instrument to be calibrated (measurand) and the Gesa standard.

- Measurement uncertainties in each point.

A) Calibratable instruments

A huge number of different instruments can be calibrated in Gesa. Before you send us the instrument you want to have calibrated, please ask us in order to check if it can be calibrated. The limitations might appear due to the next reasons:

- The instruments’ accuracy or resolution is higher than the standards that can be handled in Gesa. As a rule, the standards must be an order of magnitude higher in accuracy and resolution than the instrument to calibrate. (Read section D), “equipment used in the calibrations and standards of Gesa”)

- Dimensions or construction of the device.

- The instrument might need to be repaired before being able to be calibrated. If that is the case, a previous quotation would be needed.

We perform calibrations in the next areas:

Temperature and humidity

- Platinum resistance thermometer

- Direct reading thermometer with thermometric resistance sensor

- Direct reading thermometer with thermocouple sensor

- Temperature data loggers

- Direct reading thermometer with other sensors (bimetallic strip or gas expansion)

- Temperature transmitters

- Noble metal and base metal thermocouple

- Liquid column thermometers

- Direct reading thermometer (air temperature)

- Infrared radiation thermometers

- Psychrometers, hygrometers, and relative humidity data loggers

Pressure and vacuum:

- Pressure gauges, pressure transmitters and vacuum gauges.

B) Reasons to calibrate

- Expiration of the validity period

- Depletion of certain volume of use (hours of work)

- Impacts or strong vibrations that end up descalibrating the instrument

- Changes in temperature

- Whenever the obtained observations are questionable

- To comply with current regulations

C) Gesa’s internal calibration procedures

We have a calibration procedure set for each magnitude (temperature, pressure and humidity) and each kind of instrument.

Every procedure is made under our ISO 9001 quality certification. This regards the organization of the laboratory, document control, staff training, customer service…

We use the documents published by the Spanish Metrology Centre (CEM) as a guide for our procedures. The main ones are the next:

- TH-001 Procedure for the calibration of digital thermometers

- TH-002 Procedure for the calibration of infrared radiation thermometers

- TH-003 Procedure for the calibration by comparison of thermocouples

- TH-004 Procedure for the calibration by comparison of liquid column thermometers

- TH-005 Procedure for the calibration by comparison of thermometric platinum resistances

- TH-007 Procedure for the calibration of meters of humidity and temperature in air

- ME-001 Calibration of vacuum gauges

- ME-003e Calibration of pressure gauges

- ME-010 Calibration of pressure calibrators

- ME-017 Procedure for the calibration of pressure transducers with electric output

The main goal of the calibration is to estimate the uncertainties of the measurement. According to the Vocabulary of Metrology (VIM)(1) , the measurement uncertainty is "a non-negative parameter characterizing the dispersion of the quantity values being attributed to a measurand".

To calculate the uncertainty, we apply the Guide to the Expression of Uncertainty in Measurement (GUM)(2) and the EA-4/02 M:2013 document, whose main topic is the measurement uncertainty evaluation in calibrations.

The corresponding contributions of the calibration system are:

- Deviation, reading interpolation and resolution of the standards.

- Uniformity and stability of isothermal equipment, pressure pumps and climatic chambers.

The corresponding contributions of the measurand are:

- Reading uncertainty (resolution)

- Hysteresis, uniformity and/or repeatability

- Other influential magnitudes

D) Equipment used in the calibrations and standards of Gesa

All the calibration certificates must have traceability. This means that it must be possible to identify all the steps made in the calibration chain to an internationally recognized entity. In Gesa, our standards consist in traceable patterns to ENAC (Entidad Nacional de Acreditación) or UKAS (United Kingdom Accreditation Service). These standards are calibrated periodically by entities accredited by ENAC and UKAS.

- Temperature control:

- Our calibration equipment guarantees a high set-point temperature stability over time (±0,05 K), as well as great uniformity in any other point. If the quality of the equipment is high, the calibration laboratory will add a low measurement uncertainty.

- In what regards to temperature, the range that can be calibrated goes from -80ºC to +600ºC. The uncertainty of our standards is lower than 0,02ºC.

- Pressure and vacuum control:

- In order to calibrate pressure and vacuum instruments, the equipment we have is able to generate pressures whose resolution can go up to 10 Pa (0,1 mbar). The high quality of the different components of the equipment (valves, quick connectors, etc.) allows keeping stable pressures during the calibration.

- The fluids we use are air, water or hydraulic oil. The use of these fluids depends on the pressure range of the instrument under test.

- The pressure range that can be calibrated goes from -95 KPa to 60 MPa (-0,95 to 600 bar). The uncertainty of the standards is lower than 80 Pa (0,8mbar).

- Relative humidity:

- In what regards to the calibration of hygrometers, the instruments we use are climatic chambers. The temperature and relative humidity of these chambers can be regulated and controlled.

- The calibratable points are 50%RH, 60%RH and 70%RH, and the three of them are measured in a temperature between 20ºC and 25ºC.The standards have an uncertainty of 1,2%RH.

E) Periodicity of the calibrations

The owner of the instrument to calibrate is the one who decides the period of validity of the issued certificate. The duration of the certificates tends to be between six months and two years, depending on the conditions the instrument has to work in.

(1)VIM International Vocabulary of Metrology – Basic and General Concepts and Associated Terms (VIM 3rd edition).

(2)GUM – Guide to the Expression of Uncertainty in Measurement

946 766 364

946 766 364

605 080 259

605 080 259